Field Research | Shandong Ever: A Distinguished Supplier of Differentiated Functional Alginate Fibers

2026-01-22 13:41

On 20 October 2025, Chief Engineer Song Fujia of the Textile Product Development Center, Deputy Director Chen Xiaoli of the Product Development Department at the China Textile Information Centre, and Deputy Directors Ma Lei and Chen Peipei of the Product Development Department conducted their first on-site inspection of Shandong Ever Biotechnology Co., Ltd.

01 Alginate Fiber

Shandong Ever Biotechnology co., ltd was established in 2014 and specializes in the research, development, production and sale of alginate fiber and related products. These products are widely applied in various sectors such as textiles and apparel, healthcare, skincare, and safe protection.

At the research meeting, Ever presented an overview of the company’s current development, covering technological innovation, product development, and market promotion; The FCPP research team delivered a report on the establishment of innovation platforms and industrial chain collaboration. Chief Engineer Song Fujia acknowledged Ever's breakthroughs in overcoming key technical challenges for the industrial-scale production of alginate fiber, as well as its innovative application of alginate fiber in downstream industrial chain sectors. Both parties engaged in in-depth discussions on topics including product innovation, market strategy, brand development, and upstream-downstream collaboration.

02 Platform Development

Proactively fostering industry-academia-research collaboration

The company places strong emphasis on the development of R&D platforms and has been recognized as a National High-Tech Enterprise, a Shandong “Specialized, Refined, Distinctive and Innovative” SME, and a Shandong Innovative SME. It operates multiple innovation platforms, including the Weihai “One Enterprise, One Technology” R&D Center for Industrial Enterprises, the Weihai Engineering Technology Research Center for Functional Textile Auxiliaries, and the Weihai Pilot and Demonstration Base for Differentiated Alginate Fiber, among others.

Ever has established two alginate fiver production lines, which are the largest in scale and leading in output within China, demonstrating strong market competitiveness in terms of quality and process stability. The company places great emphasis on industry-academia-research collaboration, and has established cooperative mechanism with multiple universities including Qingdao University, Wuhan Textile University to jointly undertake scientific research and product development.

03 Technological Breakthroughs

Alginate Fiber Achieves Application Breakthroughs

As one of the few domestic enterprises mastered large-scale industrial production technology for alginate fiber, the company’s core technology “key technologies for the industrialization of differentiated functional alginate fiber” has been selected for the Weihai “Bottleneck technologies” key research and develop project pool.

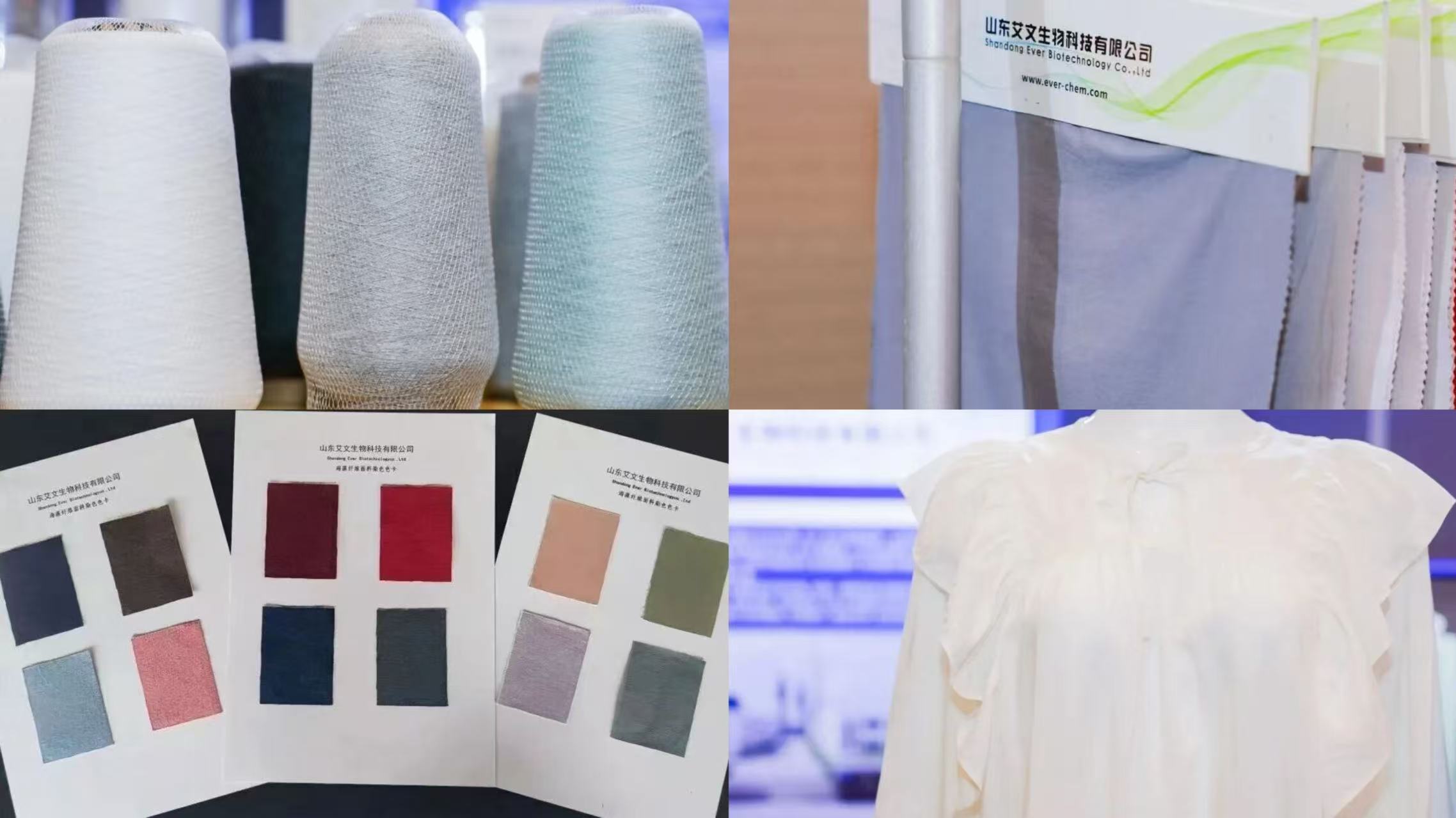

The company’s main products include alginate fiber for textiles, facial masks, and medical dressings. It has successively launched innovative products such as differentiated alginate fiber for medical and hygiene applications and alkali-resistant, hydrolysis-resistant alginate fiber.

The company has achieved abundant innovation outcomes. The product “Alginate Fiber Color-Spun Satin Bedding Set”, was selected one of the “Top Ten Textile innovation products of 2024’. The project “application of one-bath one- one step dyeing method for polyester- cotton fabrics received the certificate of excellence innovation achievement from Shandong province’s enterprise innovation achievement project repository, first prize in the Enterprise Group at the Sixth Shandong provincial Industrial Engineering Application Case Competition. The alginate fiber antibacterial socks were included in the 2024 Recommended Catalogue of Outstanding Achievements in the knitwear industry chain.

04 Intelligent Manufacturing Upgrade

Digital integration driving efficiency improvement

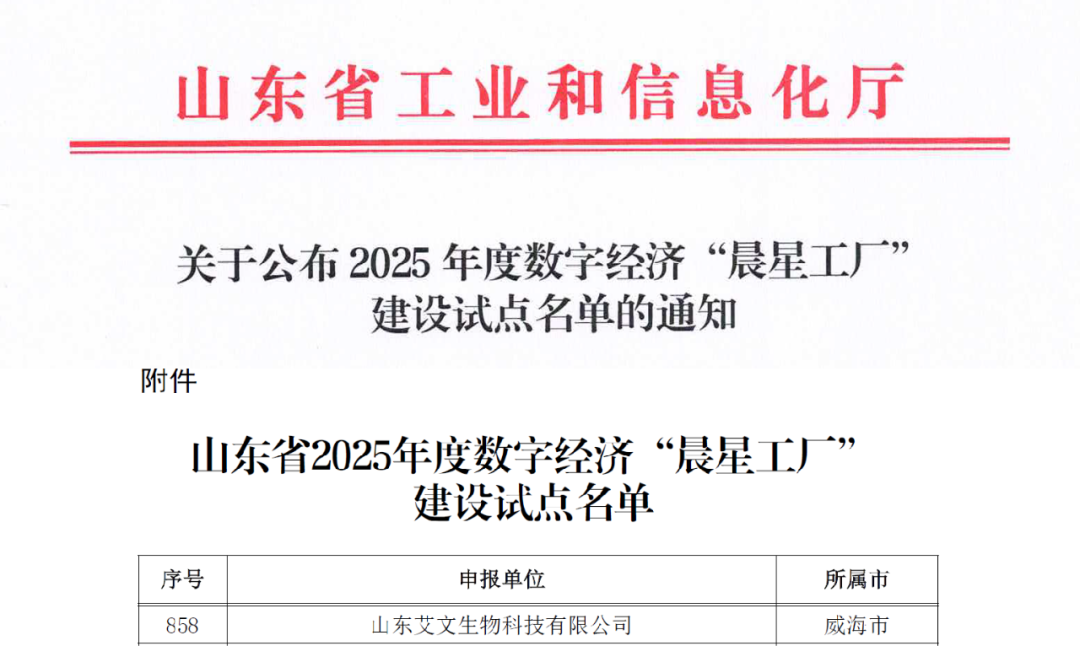

The company continues to enhance its level of digitalization and intelligent manufacturing and was successfully selected for the 2025 Digital Economy “Morning Star Factory” Pilot Program.

By leveraging MES and ERP systems and integrating industrial Ethernet with industrial internet technologies, the company has resolved key industry challenges such as high equipment heterogeneity in traditional alginate fiber production lines, low maintenance efficiency, weak remote control capabilities, and difficulty in adapting to flexible manufacturing. As a result, overall manufacturing costs of alginate fiber has been reduced by 18%–25%, while annual production capacity has increased by 20%–50% remarkably.